Nova Vector platform has the potential to capture data that has eluded manufacturers for many years. The results are greater revenue earned from higher levels of compliance, manufacturing quality, and delighted customers.

The Production Planning Module offers automated monitoring of per-shift production plan execution for connected production lines. This module allows for manual input of production plans or seamless integration with ERP systems. On the other hand, the Production Planning Optimization Module goes a step further by automatically generating an optimal production plan, sales forecast, production speed, efficiency of production lines, changeover time, and various parameters. By employing the Production Planning Optimization Module, our customers anticipate significant efficiency gains, estimating savings of 10 engineer/days per production line per month.

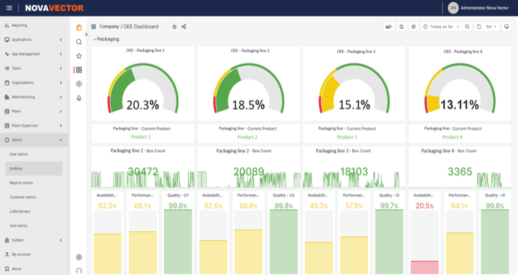

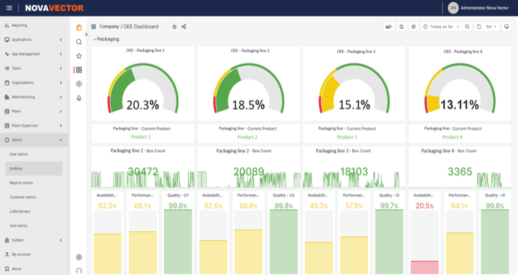

Overall Equipment Effectiveness (OEE) measures the percentage of planned production time that is truly productive. Many manufacturing lines are only 60% productive, meaning there are tremendous opportunities for improvement. Nova Vector's OEE Dashboards offer insights into overall equipment effectiveness, helping manufacturers swiftly identify and address performance bottlenecks and optimize cost and productivity. By relying on real-time data provided by Nova Vector platform, manufacturers are gaining quicker insights and can determine which areas of availability, performance and quality are most impacting performance.

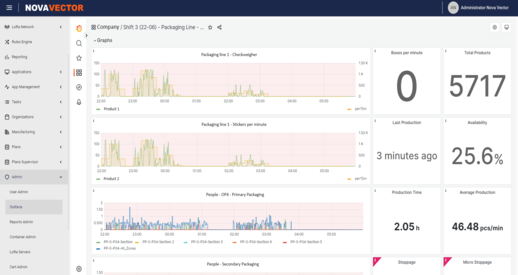

The Nova Vector platform is designed to simplify the process of recording and classifying stoppages by utilizing real-time data and predictive analytics. This allows manufacturers to identify maintenance needs in advance, reduce unplanned stoppages, and enhance productivity. By analyzing the stoppage data recorded on the Nova Vector platform, manufacturers can gain valuable insights into how to improve the lifespan of their manufacturing equipment and machinery.

With Nova Vector, manufacturers can leverage customizable reports to gain valuable insights into stoppage patterns, including types, counts, and durations. By filtering data according to production lines, products, and date/time, clients can detect trends, enhance planning, and construct strategies to minimize unexpected stoppages. This data-centric methodology promotes proactive decision-making, streamlines production efficiency, and boosts overall operational performance.

Nova Vector's real-time data visualization equips managers with instant insights to make efficient decisions. Intuitive visuals make tracking factory operations effortless, allowing for proactive responses and enhanced operational efficiency.

Nova Vector streamlines maintenance crew task tracking and analysis with RFID readers and ID cards. The maintenance crew can easily record activities, enabling efficient monitoring and analysis of tasks and outcomes.

Nova Vector's Real-time Plan Execution Tracking, using RFID card readers, makes maintenance crew task monitoring more manageable. A quick swipe records activities and provides real-time updates on task execution, increasing visibility, control, and maintenance efficiency.